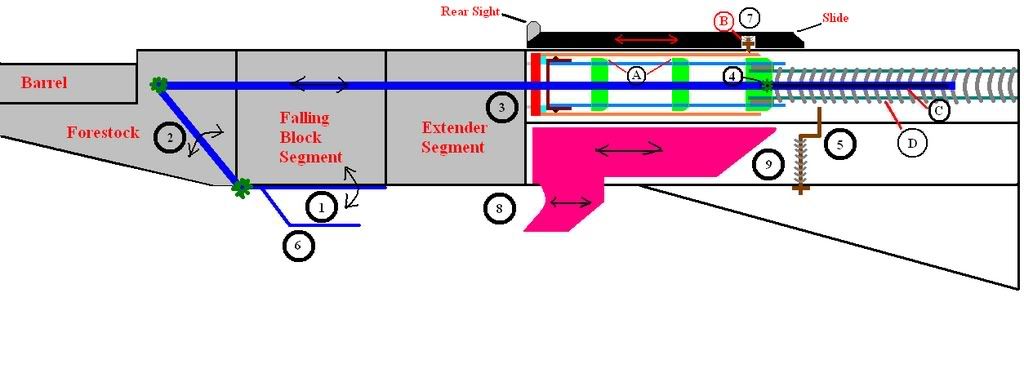

Okay, I finally finished the diagram for the cocking mechanism of the FBBLR. I wanted to have multiple pictures depicting the whole cycle, but this took long enough by itself. Hmm...looking at the picture once I finished it, it seems to be way out of proportion. Anyway, here it is:

I have no good idea of what materials I'm going to use (other than a ton of PVC and/or CPVC, some springs, and maybe even some wood), so I didn't make a color key or anything like last time. I'm going hardware store-hopping this weekend, and hopefully I'll be able to figure it out. Once I do, I'll update.

Here's the explanation:

1. As I mentioned last time, this lever allows the falling block to lower when it is lowered. Once the block is in this position, a dart can be loaded into it. If you don't know, a similar mechanism is used in real rifles. The Sharps rifle was one of the early breech-loading rifles, while the Ruger No. 1 is a modern example. The real bullet is actually inserted into the barrel in front of the falling block, and the block itself was merely used to seal the breech.

2. As the lever is lowered, an internal armature (which is attached at an angle to the lever) rotates backwards (toward the butt stock and the plunger assembly within).

3. The armature forces this "cocking bar" back.

4. The bar is attached to the plunger. It pushes the plunger a portion of the way back.

5. This piece of music wire is set up like Bolt Sniper's SCAR-N. It will lock in front of the rearmost of the two catch faces (A) and thus keep the plunger back until the trigger is pulled.

6. At this point, the block will have been lowered and the dart can be loaded into it. Closing the lever will raise the block and pulls the bar back to the pictured position. Remember that, at this point, the plunger will be back of where it is pictured. For this reason, a slot (C) will be cut in the cocking bar. It will allow the plunger to remain motionless while the cocking bar moves back and forth. Also, it allows for the plunger to move forward when the gun is fired.

In fact, at this point the gun

can be fired. However, this should only be done at short range. This is because the rotational motion of the armature cannot provide enough horizontal motion to push the plunger all the way back. There will not be enough air.

7. So, if you're in a hurry and only need a short range shot, using the lever action alone will provide a good rate of fire (although sacrificing range). But if you need a longer range shot, then you'll need an extra step before firing.

Pulling the slide back will cock the rifle fully by using the mechanism at B. This is is a piece of music wire that will engage with one of the catch faces. When pulled back all the way, the forward catch face will engage with the catch at 5. Once you let go a spring will bring the slide forward, and the beveled edge of the wire will allow it to return to it's resting place.

8. Now, the rifle is ready to fire at long range. Simply pull the trigger...

9. And the beveled trigger plate will push down on the catch, releasing the plunger.

D. This here will be some sort of piping that keeps the spring from buckling. I'll call it a "support tube." It will be fixed to the back of the butt stock, but able to slide within the plunger. It will be substantially smaller than the inner diameter of the plunger. Something else (such as a piece of piping that has a size between the plunger and the support tube) will push against the spring.

Overall Concerns:

My biggest concern is the lever-action cocking mechanism. It may not provide enough air to even provide a short-range shot. In fact, the dart may not even leave the barrel. In this case, the lever-action cocking will be pretty much useless. Also, even if it does work, I may have some trouble connecting the armature to the cocking bar. I can't think of how to explain the possible problem, so I'll just say that it's a problem with the fact that the armature is rotating. If it gets to be too much trouble, I'll probably just skip it entirely and use the slide alone for cocking the rifle.

Also, I'm a little worried about the size of the plunger chamber. I don't want it to be too long, because then the butt stock will have to be too long and I won't be able to reach the trigger. At the same time, it can't be too short or else the range will be complete crap. I definitely want at least 70 feet, but it's possible that I won't even get 20 feet.

That's all that I can think of for now, but like I said before I'll probably find a lot more problems once I start building the thing.