Here it is... I finished this bad boy in like, July, and am posting now because I have no school. So, here is what you need. To do this, you only

need the 1/2" PVC, 1/2" CPVC, and a Dremel, but I like the other stuff because of my large hands.

- 1/2" CPVC barrel (attached firmly to a gun)

- 1/2" PVC *not thin wall*

- 1/2" PVC coupler

- 1" PVC coupler

- 3/4" PVC T coupler

- Dremel

Here is what you are building...

First Step: Attach the 1/2" PVC coupler into the 3/4" PVC T coupler... Then the 1" PVC coupler on the the T coupler. It should all fit very snug, like a 1/2" CPVC and 1/2" PVC coupler.

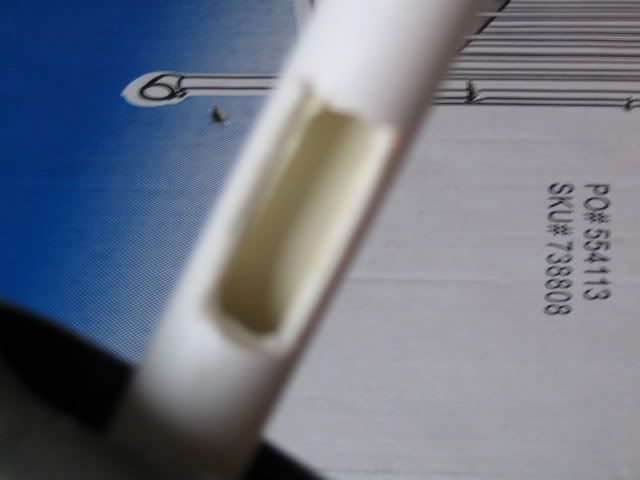

Step 2: Take 5 inches of 1/2" PVC and cut a hole into it. The size can vary depending on the size of your dart. Mine is about 2" to accommodate

all dart sizes.

Step 3: Dremel the 1/2" PVC out. This took me about 20 minutes because my Dremel doesn't work well under pressure and heats up very fast. If you have a drill or something you could probably make that work, but my Dremel's sanding drum is the perfect size. You are going to need to smooth the opening where you cut it before so the darts don't rip when you put them in.

Step 4: Cut the same size hole into your CPVC barrel. Should be close.

Step 5: Attach your 1/2" PVC to the T coupler, and couplers. This step isn't necessary but I like it because it is a quick way to open/close the breech.

DONE!

DONE!Open breech:

Closed:

(That red blur is my little brother)

Edit: After you sand your 1/2" PVC out, it should fit so snug that you here a squeak when you turn the breech.